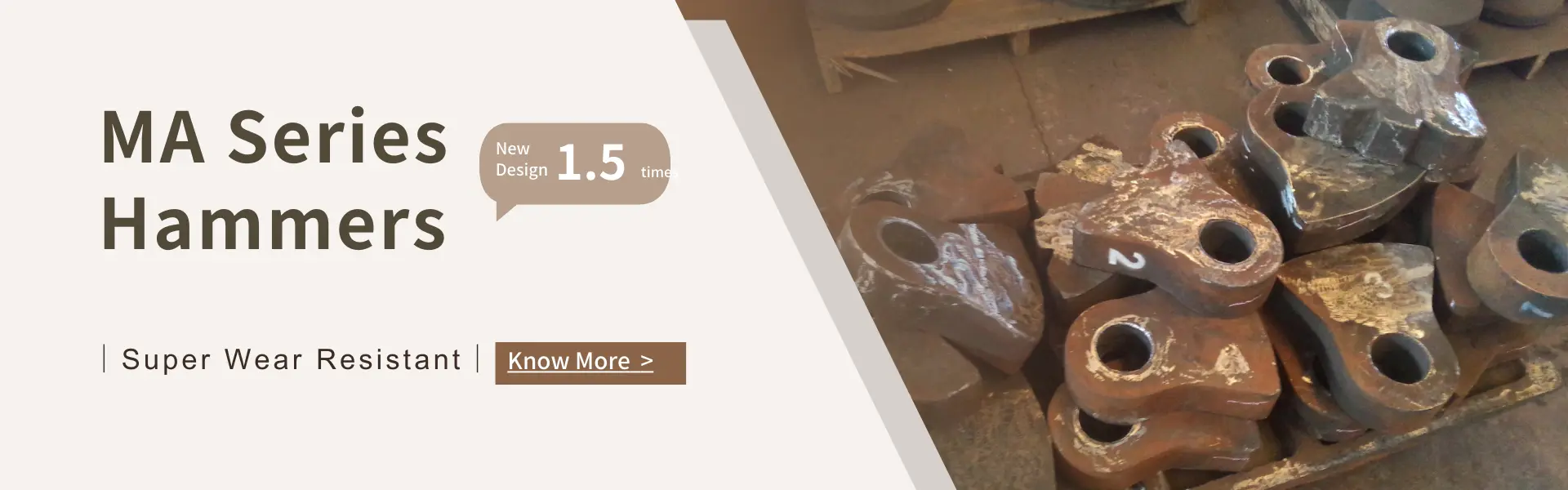

MA Series Hammers

The MA series hammers by CH Casting are a premium line of high manganese steel hammers, meticulously manufactured to deliver outstanding performance in demanding industrial applications. These hammers are specifically designed to provide exceptional hardness, toughness, and wear resistance, making them the ideal choice for heavy-duty crushing and pulverizing tasks.

The MA series hammers are crafted from high-grade manganese steel alloys, carefully selected for their superior mechanical properties. Through advanced manufacturing techniques and precise heat treatment processes, CH Casting ensures that these hammers achieve optimal hardness levels, ranging from 200 to 600 Brinell hardness (HB). This hardness, combined with their toughness, enables the MA series hammers to withstand high-impact forces and resist deformation, ensuring reliable and long-lasting performance.

Moreover, the MA series hammers undergo a specialized work hardening process. This unique feature allows the hammers to self-harden during use, enhancing their wear resistance and prolonging their service life even in the harshest operating conditions.

Designed with precision engineering, the MA series hammers are tailored to deliver exceptional strength and durability. They exhibit excellent resistance to abrasion and can effectively crush and pulverize a wide range of materials, including rocks, ores, minerals, and construction debris.